Some (quick & dirty) notes taken while installing/porting ddPrint on a Anycubic i3m (S) printer

The anycubic i3 mega S is the successor of the anycubic i3 mega model. They are mostly the same, the mega s model has:

- Different feeder (E3D Titan)

- A spool holder

- more? other mainboard?

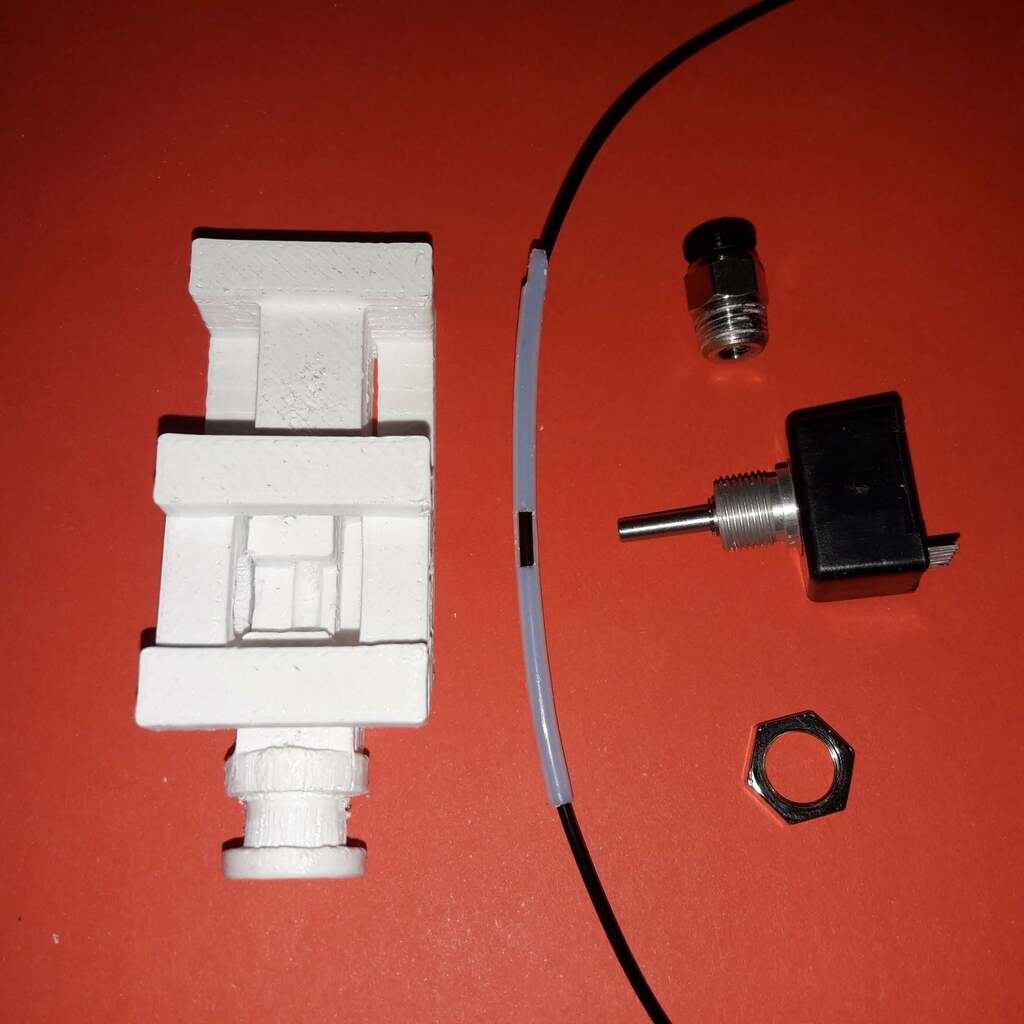

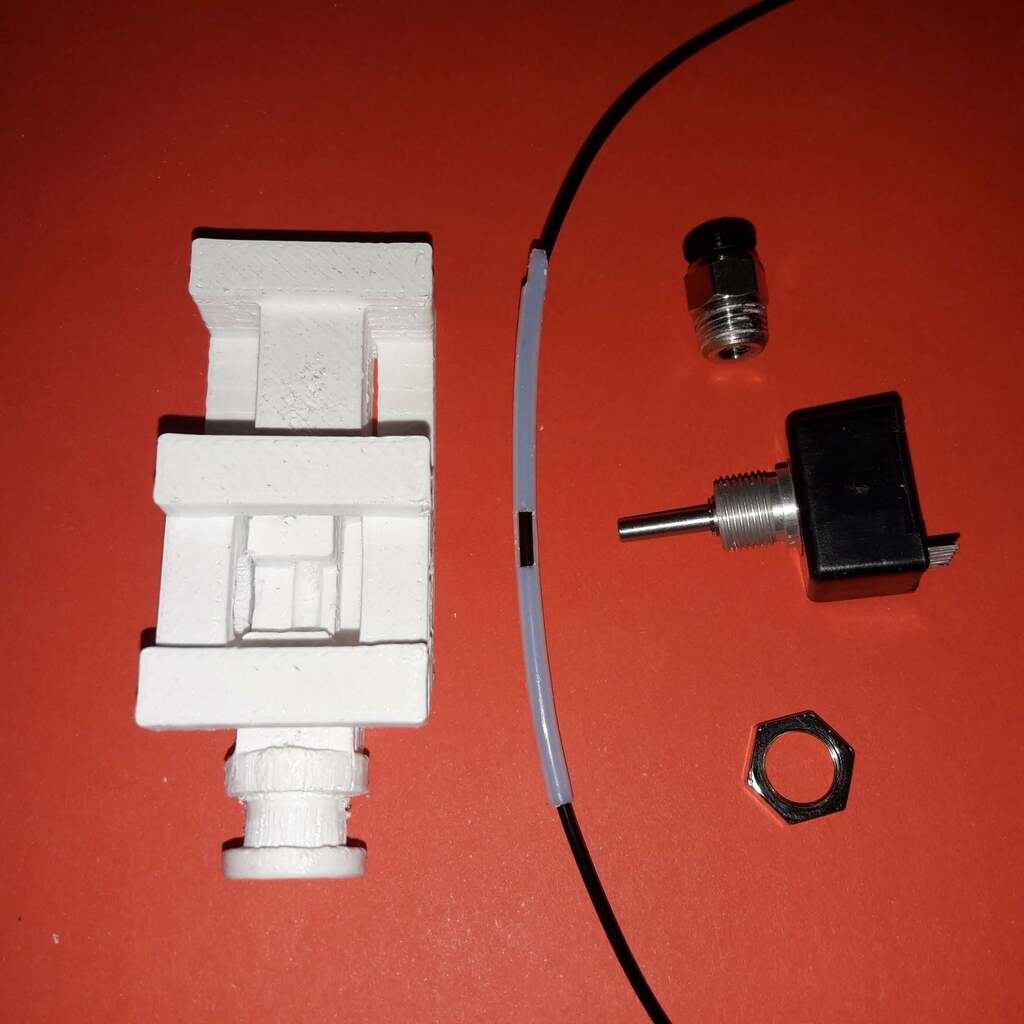

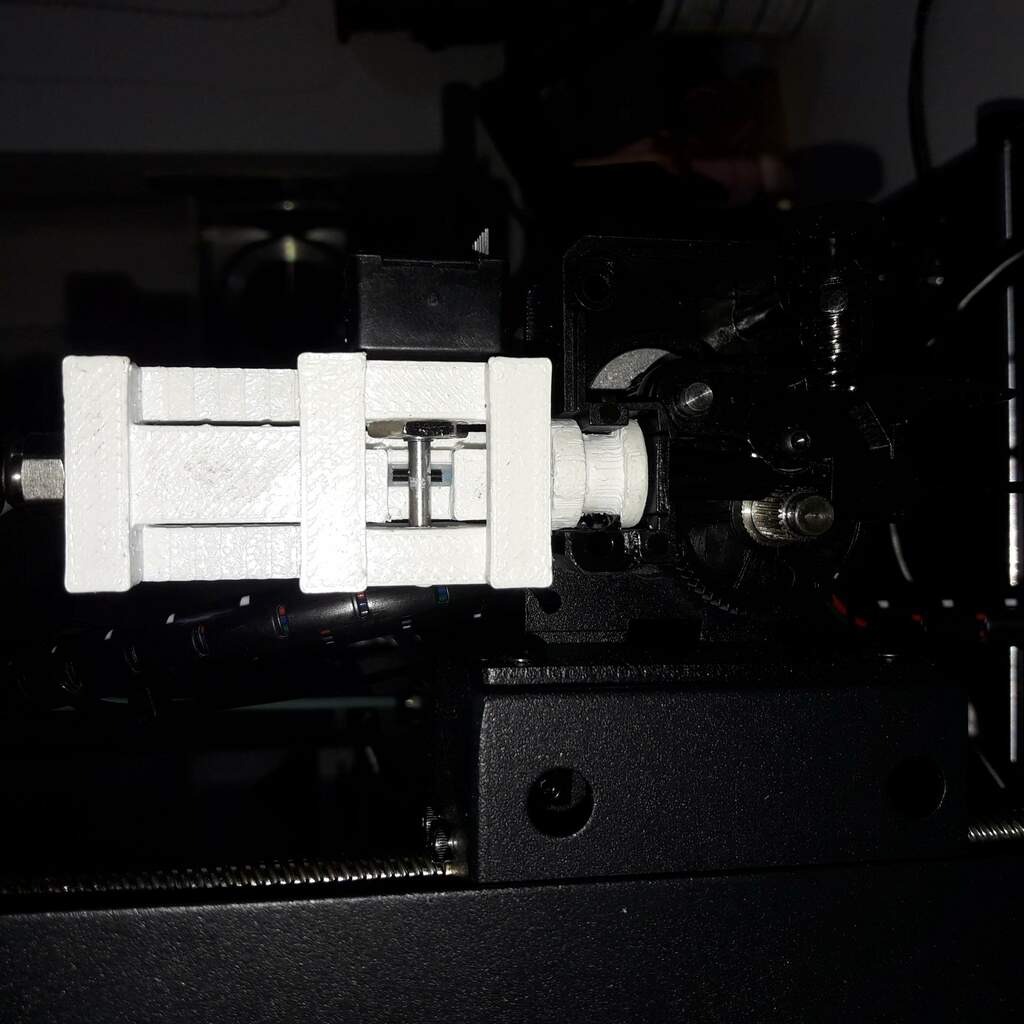

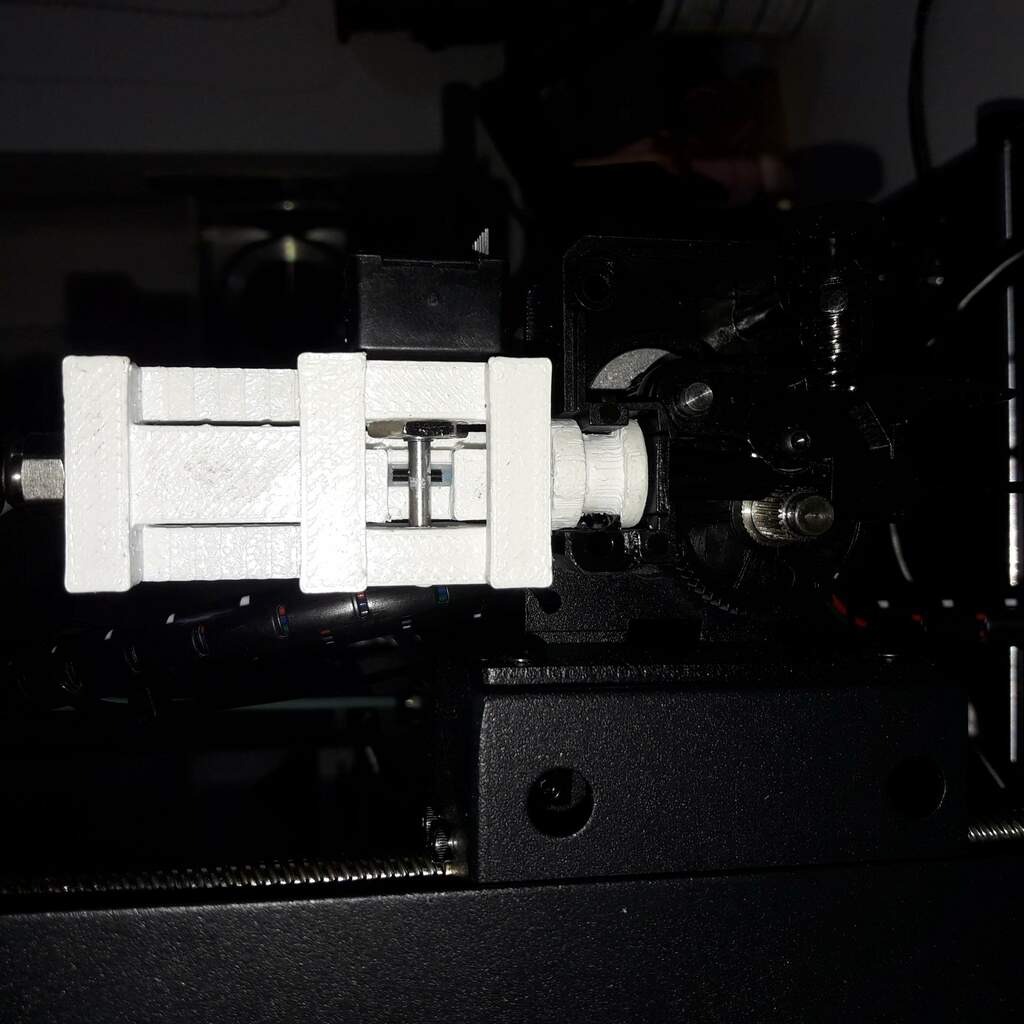

Mount Flowrate sensor

Print sensor housing and mount incremental sensor. Feeder has a E3D V6 adapter outlet and we re-use the pneumatic coupler with 10mm thread. A short 2/4mm bowden piece is inserted between feeder and FRS.

Todo: Upload and link Sensor housing stl.

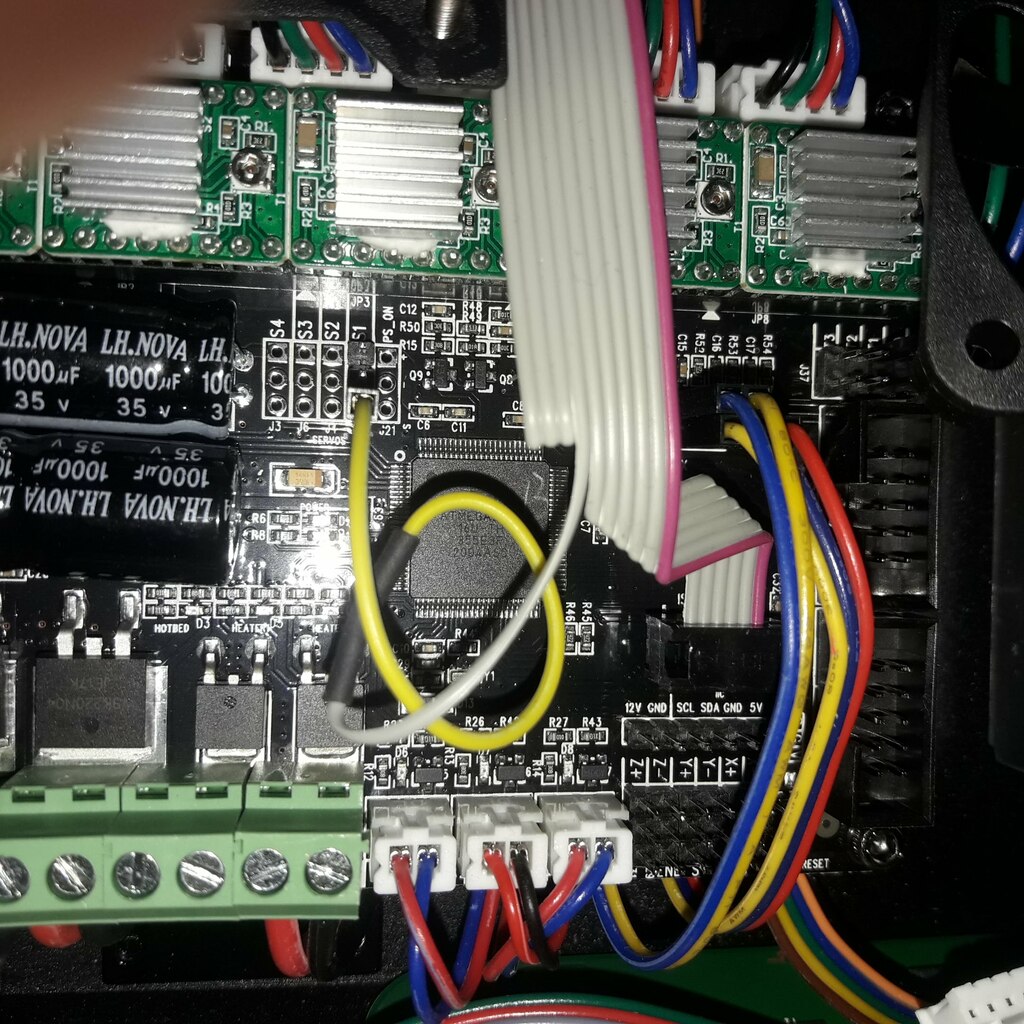

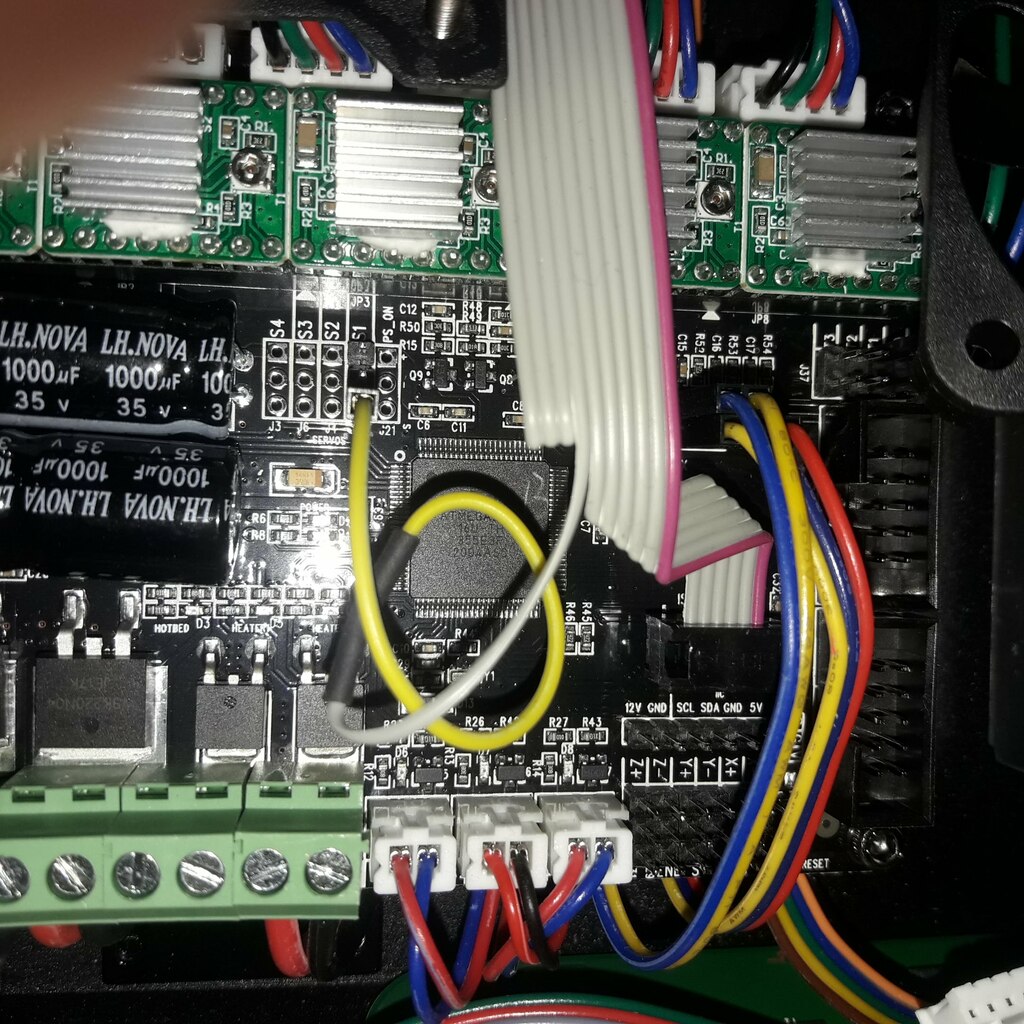

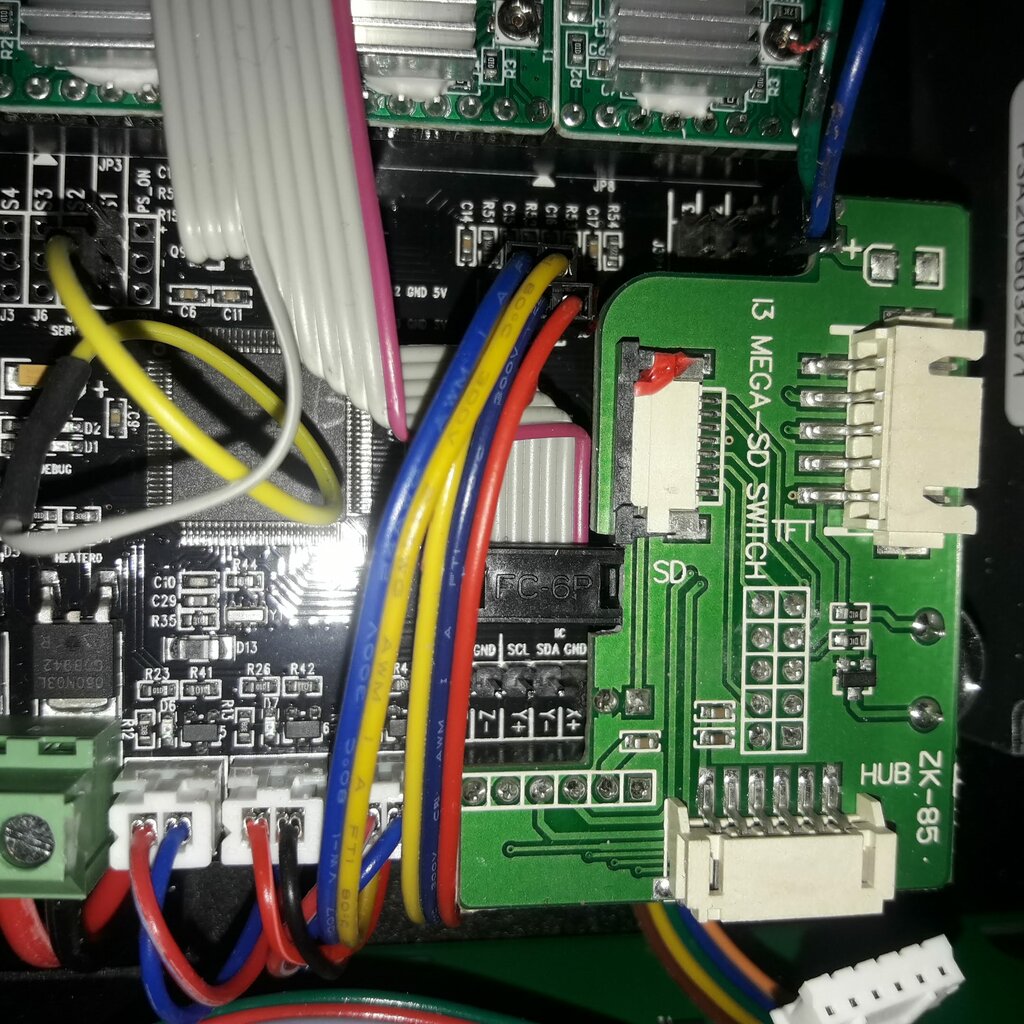

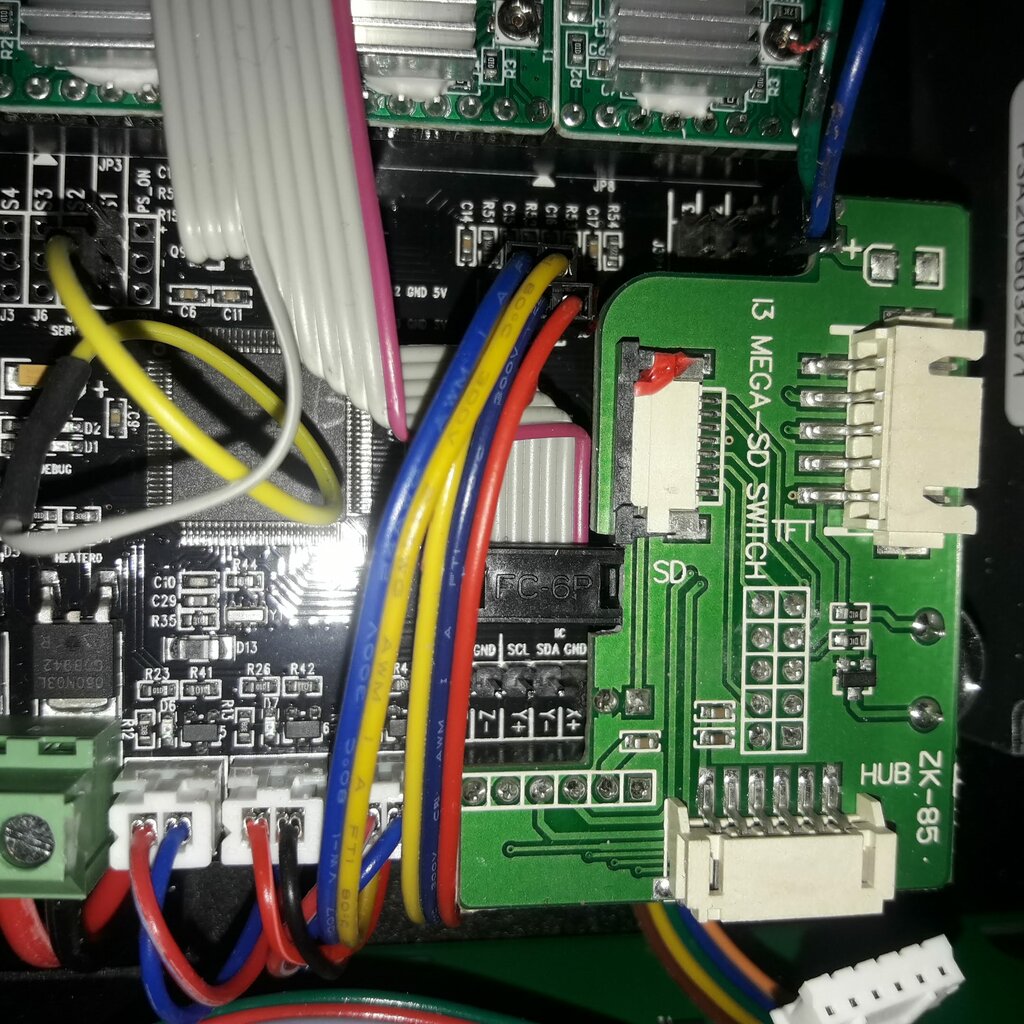

Mainboard

TriGorilla V0.0.2 (TriGorilla 1.0?) CPU: Atmega 2560 Clock: 16 Mhz

| Note: | Labeling on the PCB for D42 and D43 (endstop pins) is reversed. |

|---|

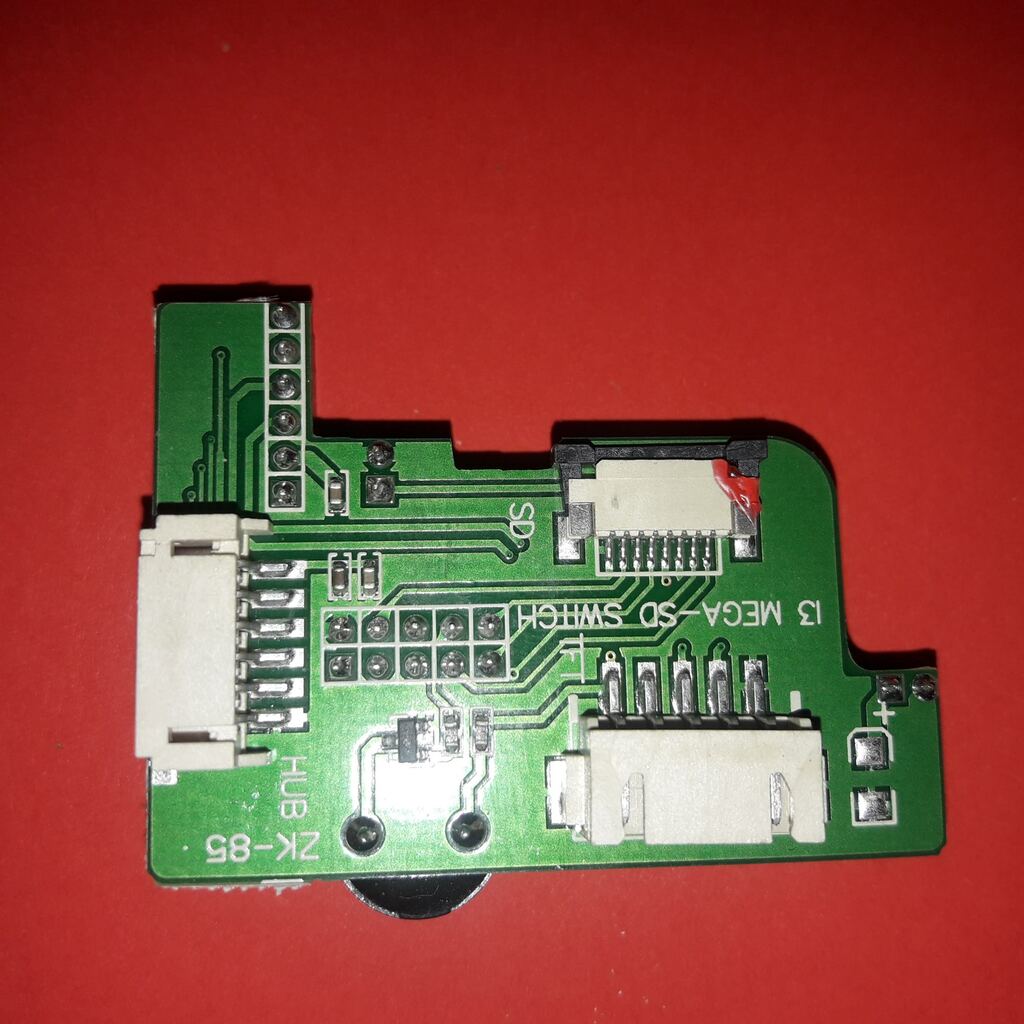

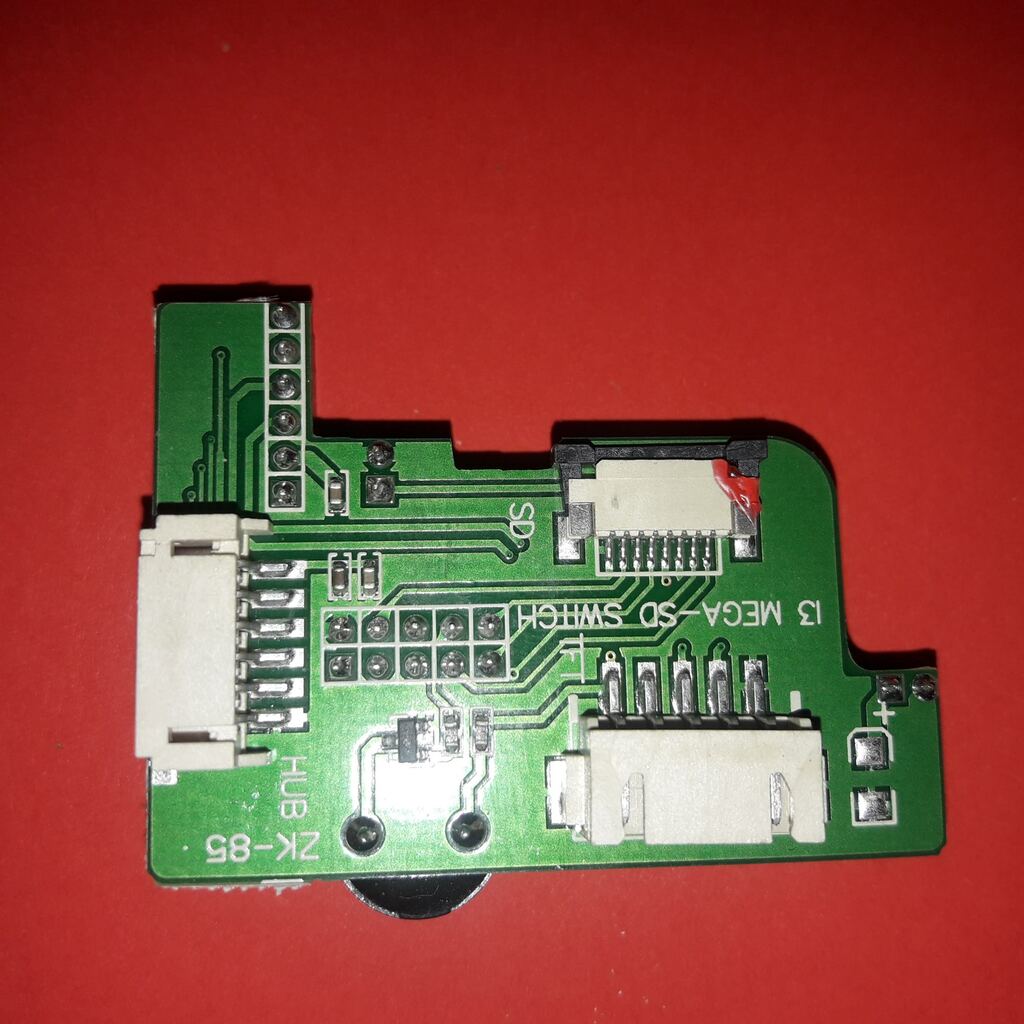

SD card is on external "I3 Maga-SD Socket V1.2" board with a 74HC4050 driver. SPI-MISO signal is connected directly to SPI bus.

Other board: "I3 Mega-SD switch Board".

Mainboard has a green debug led (connected to arduino pin D13).

Usb-Serial chip

CP2102 USB to UART Bridge Controller.

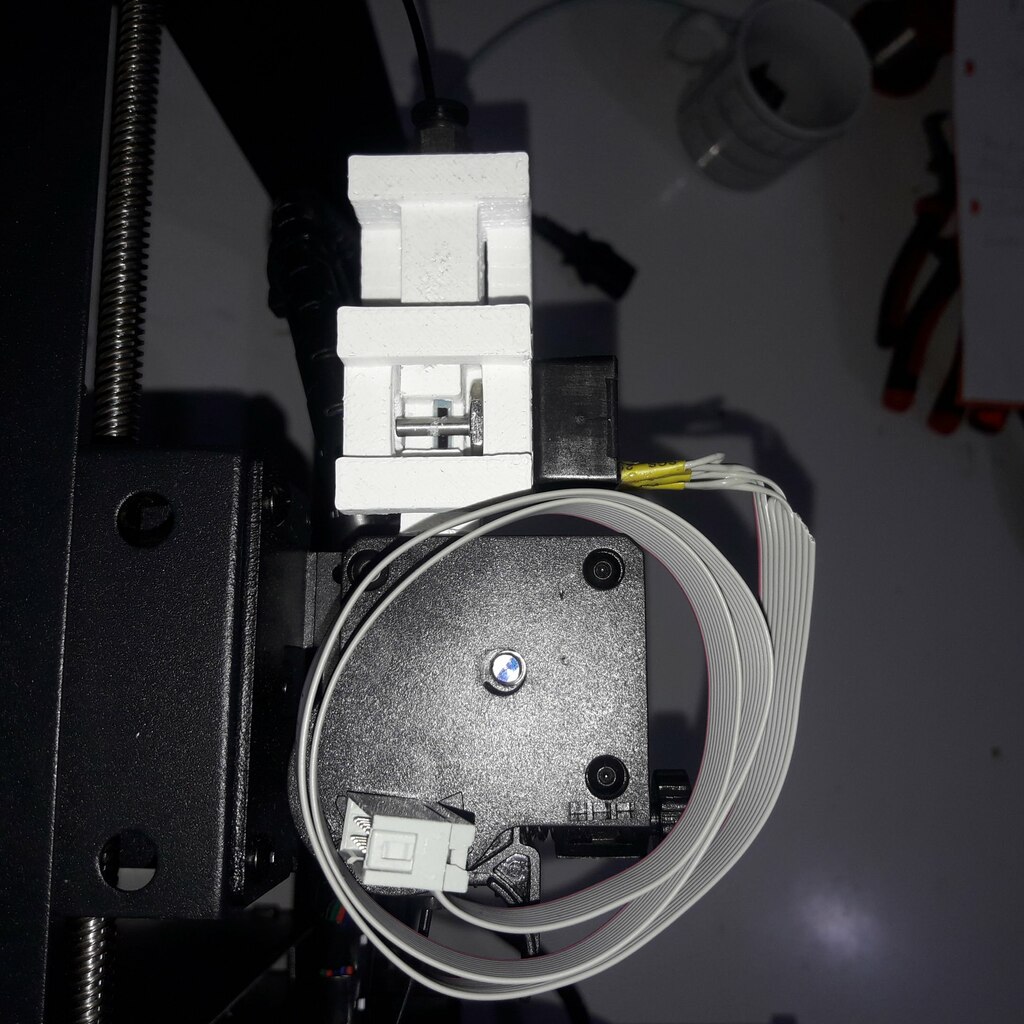

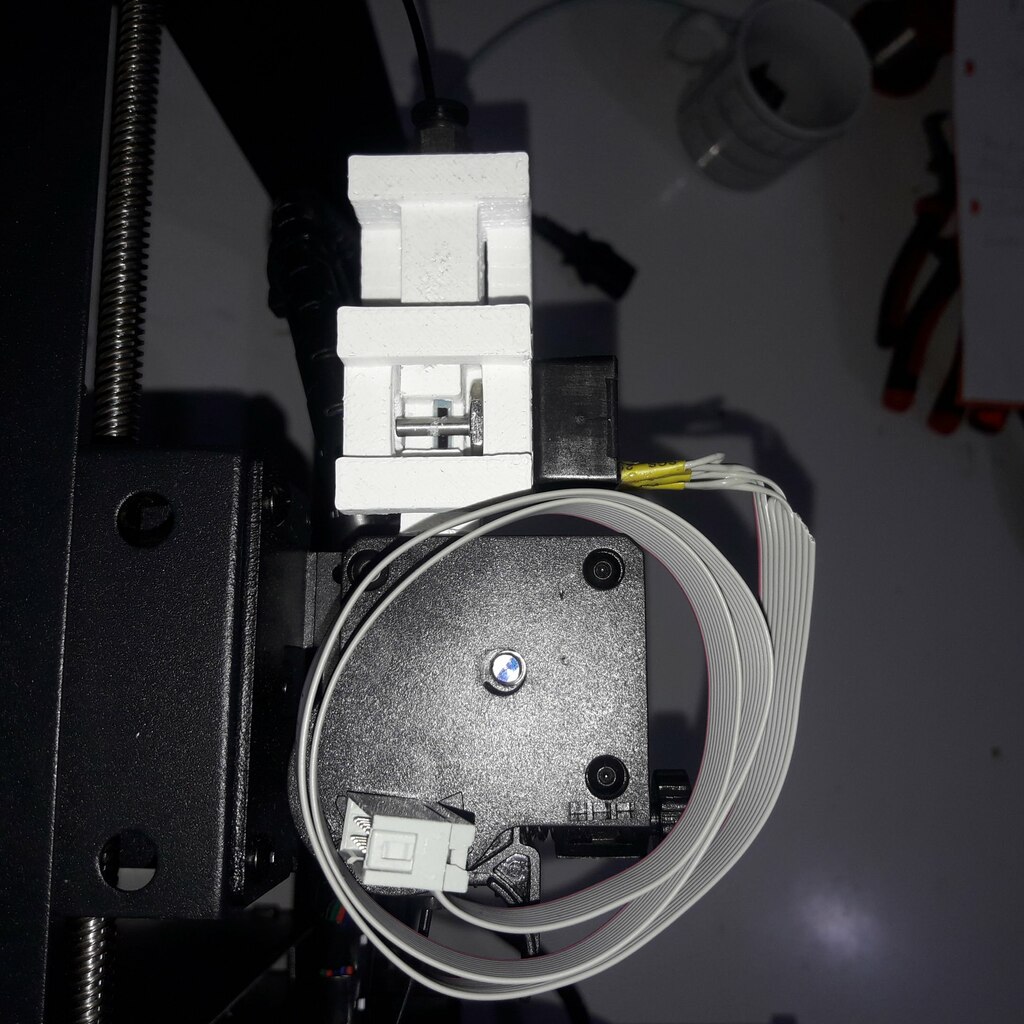

Flowrate sensor connection

No board schematic available (or does somebody has one?).

FRS is connected tho the SPI bus using 6-pin ISP header and one pin of the servo S1 header (arduino pin D11).

Connector ISP: 1: MISO --> FRS MISO 2: +5V VCC --> FRS +5V 3: SCLK --> FRS SCLK 4: MOSI 5: Reset 6: GND --> FRS GND Connector servo S1: S: Servo pulse --> FRS ChipSelect

FRS connected to mainboard headers ISP and S1:

| Note: | Had to make a small coutout on the "I3 Mega-SD switch Board" to make room for the ISP connector: |

|---|

Hotend

"V5 J-Head", 40W heater.

Thermistor types

Bed: 1 : 100k thermistor - best choice for EPCOS 100k (4.7k pullup), B57560G104F.

Generate thermistor table with:

scripts/thermistor_table.py EPCOS_100k_B57560G104F "EPCOS 100k (4.7k pullup), B57560G104F" "EPCOS_100k_4_7k" > /tmp/tt.c

Hotend: 5 : 100K thermistor - ATC Semitec 104GT-2/104NT-4-R025H42G (Used in ParCan & J-Head) (4.7k pullup)

Generate thermistor table with:

scripts/thermistor_table.py ATC_Semitec_104NT "ATC Semitec 104GT-2/104NT-4-R025H42G (4.7k pullup)" "ATC_Semitec_104NT_4_7k" > /tmp/tt.c

Feeder

Feeder is "Titan Extruder", outlet with E3D V6 style adapter, feeder wheel diameter is 7.3 mm (from https://wiki.e3d-online.com/Titan_Assembly).

Feeder spring setting: relieve tension, then set tension by three turns of the thumbscrew.

Z Axis

Two z-motors and two z-endstops.

Readout of marlin settins

Settings of the factory installed marlin firmware:

echo:Steps per unit: echo: M92 X80.00 Y80.00 Z400.00 E384.00 echo:Maximum feedrates (mm/s): echo: M203 X500.00 Y500.00 Z8.00 E60.00 echo:Maximum Acceleration (mm/s2): echo: M201 X3000 Y2000 Z60 E10000 echo:Accelerations: P=printing, R=retract and T=travel echo: M204 P3000.00 R3000.00 T3000.00 echo:Advanced variables: S=Min feedrate (mm/s), T=Min travel feedrate (mm/s), B=minimum segment time (ms), X=maximum XY jerk (mm/s), Z=maximum Z jerk (mm/s), E=maximum E jerk (mm/s) echo: M205 S0.00 T0.00 B20000 X10.00 Y10.00 Z0.40 E5.00 echo:Home offset (mm) echo: M206 X0.00 Y0.00 Z0.00 echo:Z2 Endstop adjustment (mm): echo: M666 Z0.00 echo:Material heatup parameters: echo: M145 S0 H180 B70 F0 M145 S1 H240 B110 F0 echo:PID settings: echo: M301 P15.00 I0.95 D65.00 echo:Filament settings: Disabled echo: M200 D1.75 echo: M200 D0

Bill of materials

FRS:

- EMS Sensor

- FRS housing

- 10mm pneumatic couple (unscrewd from the existing E3D adapter)

- 3/2mm ptfe liner

- 4/2mm ptfe liner

- Ribbon cable and connectors

Nice to have

- Stronger heater (50W)

First prints

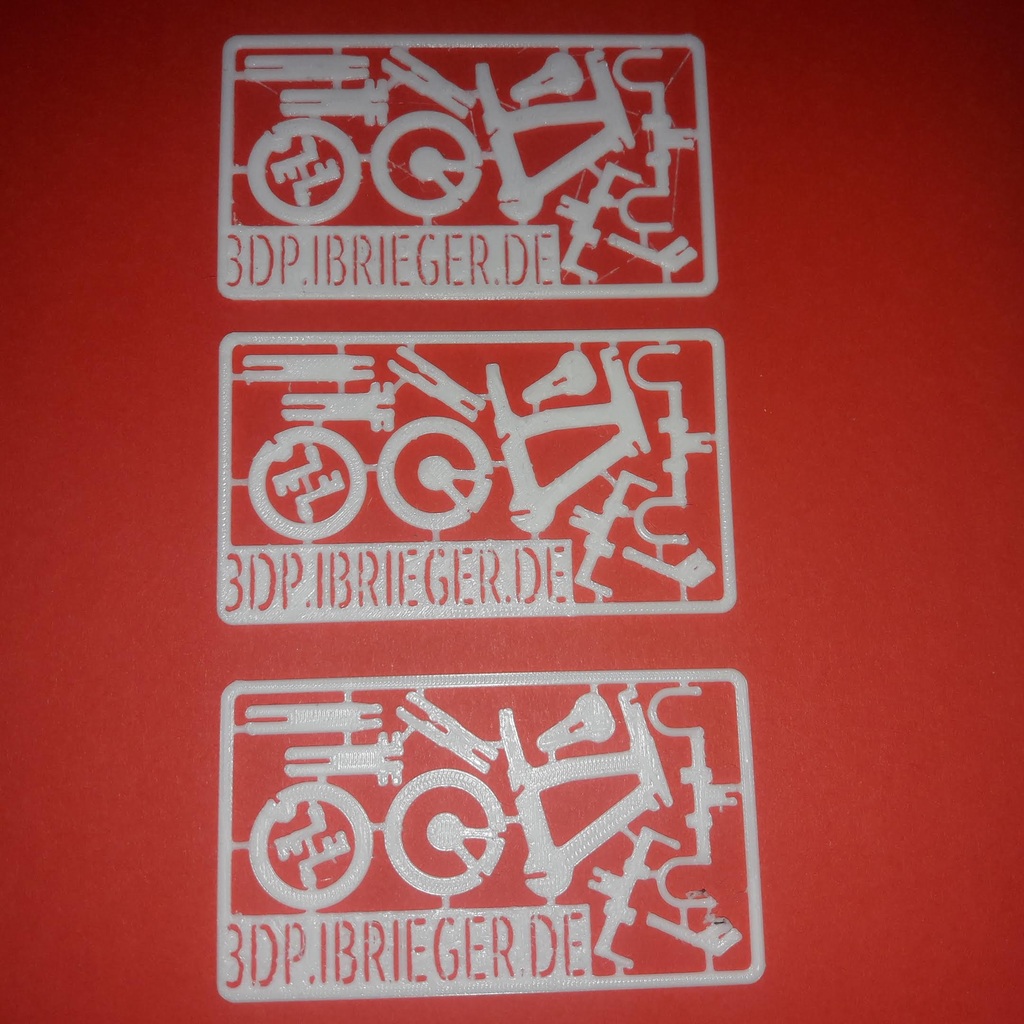

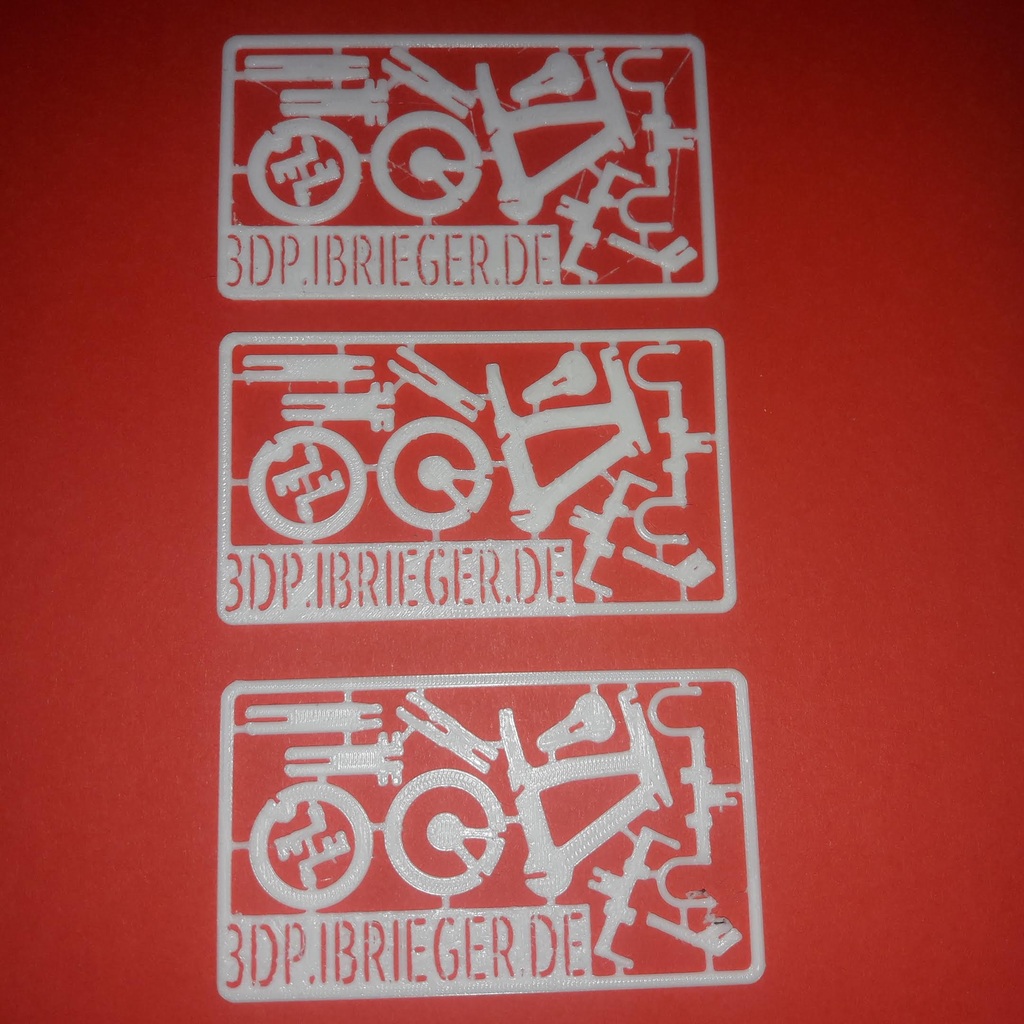

Some first prints done with the Anycubic I3M ddPrinter.

Bicycle business card (https://www.thingiverse.com/thing:1366876), printed with 0.4 nozzle, 0.2mm layerheight and 60mm/s feedrate: